Diagnostic Equipment Manufacturers

Simplifying vehicle diagnostics.

For many years manufacturers of automotive test and diagnostic equipment have trusted HaynesPro data to give their products significant advantages over their competition. The inclusion of our Vehicle Electronics Smart Assistant (VESA) and Smart data enables technicians to work faster and more efficiently, thereby saving time and money.

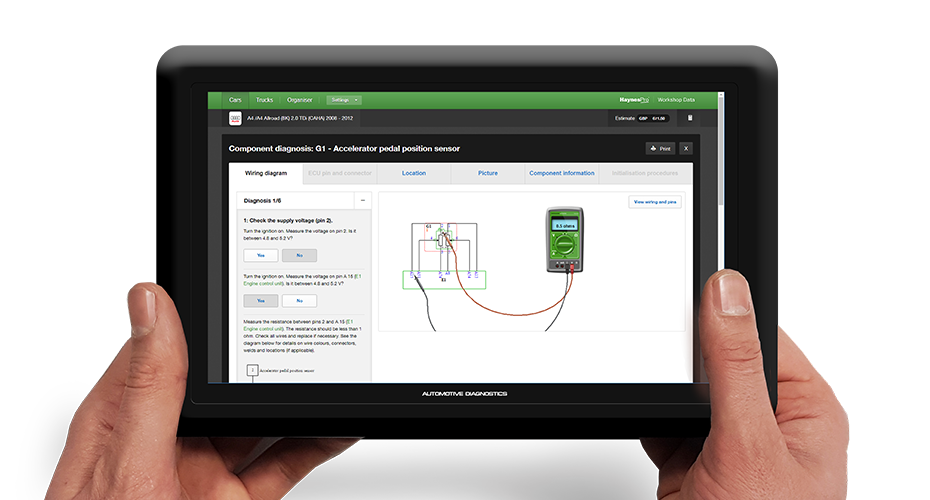

Due to the structure of many workshops, a technician working on a vehicle may not have easy access to the technical data needed for carrying out a task. He will often have to print out the necessary documents and take them to the vehicle. This is not the most efficient method of working. However, HaynesPro has a solution, growing rapidly in popularity, which lies at the heart of the company’s philosophy of improving efficiency. Today’s diagnostic devices are far more portable as they are often available in tablet form or are run on laptops. By connecting the device to a vehicle’s OBD port, the technician can review the vehicle’s fault codes.

VESA MKII

Resolving a malfunction by more than a fault code and description alone.

Using the fault code as a starting point, VESA generates type-specific diagnostic solutions. The fault is used as the basis for defining the most logical diagnostic path. By selecting either a fault code or a component, the user launches a simple, step-by-step wizard that guides him through the overall diagnostic process.

Taking the extra step

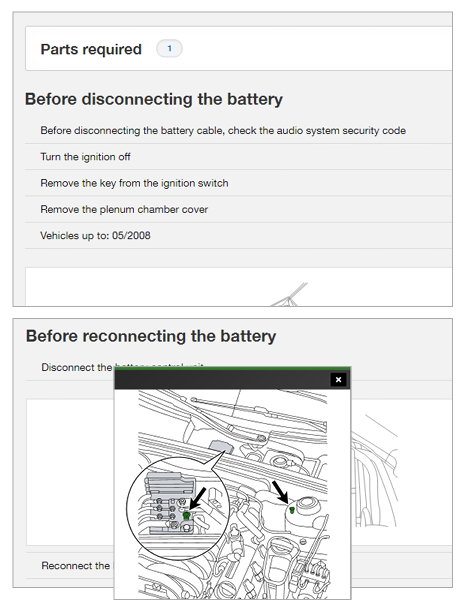

A technician’s work doesn’t begin and end with fault code diagnosis and repair. For this reason, HaynesPro is making other fault diagnosis and repair procedure data available to diagnostic suppliers. Tasks include timing belt removal/replacement, battery disconnection and equipment initialisation. With the available link to industry standard generic part numbers, a three-way link between the diagnostic tool, the technical data, and the parts catalogue, can only enhance workshop efficiency.

Offering Flexibility

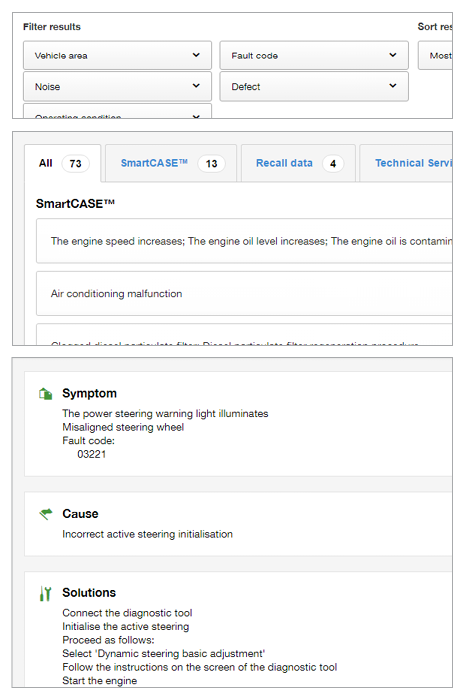

Customers can choose different levels of integration. For example, some customers may only want Service Bulletins or Cases to be displayed. In this situation, the technician diagnoses the vehicle fault via the OBD port, examines the fault codes and interrogates them against the data in HaynesPro’s SmartFIX (Technical Service Bulletins), and in SmartCASEs (verified fixes and tips), to see if an issue corresponds with any of the data therein. In the unlikely event that no relevant data is found, the technician can use the normal diagnostics mode, following the OEM’s recommended diagnostic path.

Other customers may wish to integrate the mechanical data to supplement the electronic data already available to them.

HaynesPro-integrated diagnostic tools features:

Intelligent links to diagnostic testing equipment at system and fault code level

Clear instructions on how to measure values and compare these to default values (diagnostic steps)

Local diagrams for each component, showing relevant information only (including power and ground)

Direct links to component locations and fuses and relays

Components are processed in a logical order – the most likely culprit is shown first

Standard link(s) to industry standard generic part numbers (for data export to a parts catalogue or ordering system).