WorkshopData™ Electronics

Helps technicians identify, locate and resolve electrical system and component errors using intelligent data applications.

With electrical systems and advanced technologies becoming an increasingly significant feature in modern trucks, WorkshopData Electronics has become an essential application for technicians. At its heart lies HaynesPro’s unrivalled Vehicle Electronics Smart Assistant (VESA™).

|

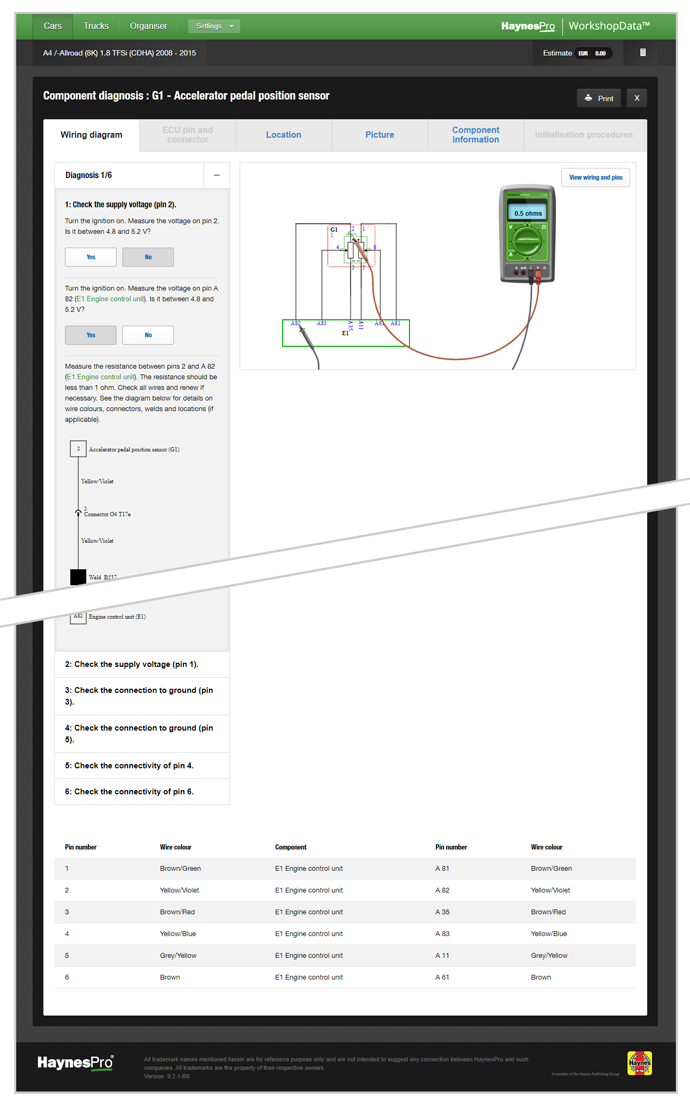

VESA guided diagnostics |

|---|

VESA™ is an innovative electronics diagnostics application. It retrieves data from the vehicle’s CAN-Bus system to help technicians diagnose faults and component errors which have generated fault codes. Up to seven fault codes can be entered simultaneously. VESA™ then presents the technician with descriptions of the fault codes, together with a suggested list of components to test.

| Subject | Feature |

|---|---|

VESA™ MK II (Guided diagnostics) VESA™ MK II (Guided diagnostics) |

|

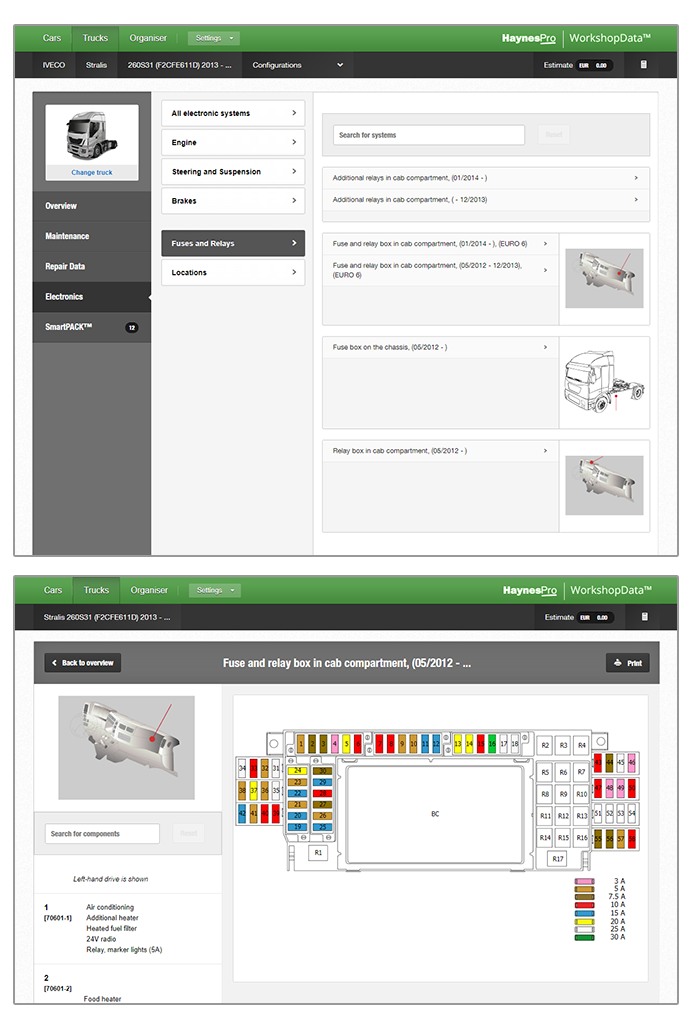

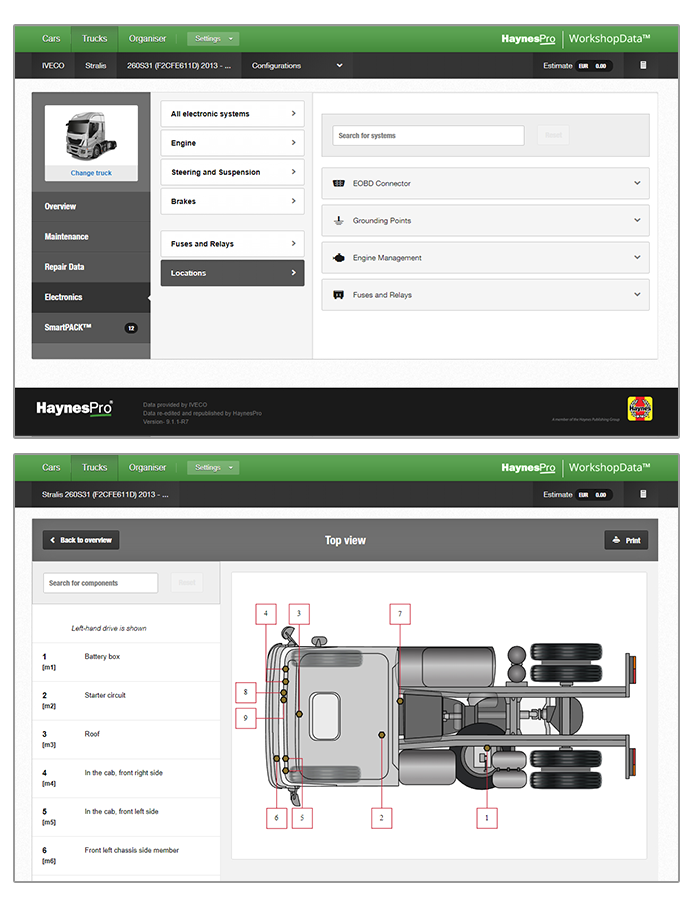

Fuses and relays

Clear fuse location and identification feature.

Fuse boxes may be installed in various locations on a vehicle and finding them can be a challenge. Using the Fuses and Relays data in WorkshopData Electronics minimises the time spent on searching.

| Subject | Feature |

|---|---|

Fuses and relays Fuses and relays |

|

Locations

One of our goals is to help our customers reduce their unbillable hours. This means minimising the time spent on searching for ground points, control units or the EOBD connector location. HaynesPro’s electronic data speeds up this process by offering direct links to such locations.

- EOBD connector location

- Ground point locations

- Control unit locations

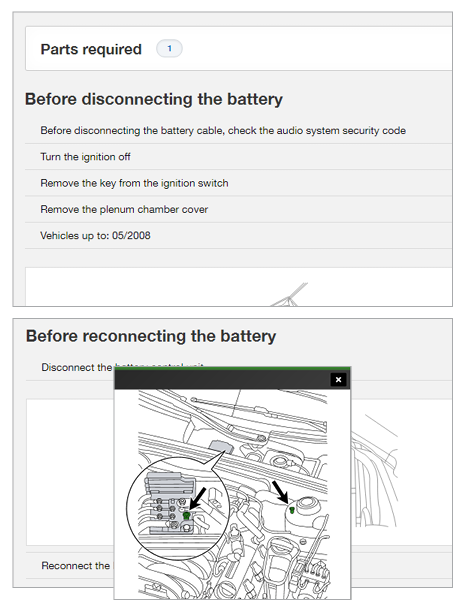

Electronic Procedures

Disconnecting/reconnecting a battery is becoming an increasingly complicated task on modern trucks. A technician needs to know the correct procedures to follow after reconnecting a battery. This ensures that no customer will have to return their vehicle to the workshop because of subsequent errors in systems such as parking assistance.

Due to the growing number of hybrid vehicles on the market, technicians also need specific instructions on how to work safely on these vehicles.

- Battery disconnection/reconnection procedures

- High-voltage circuit deactivation procedures

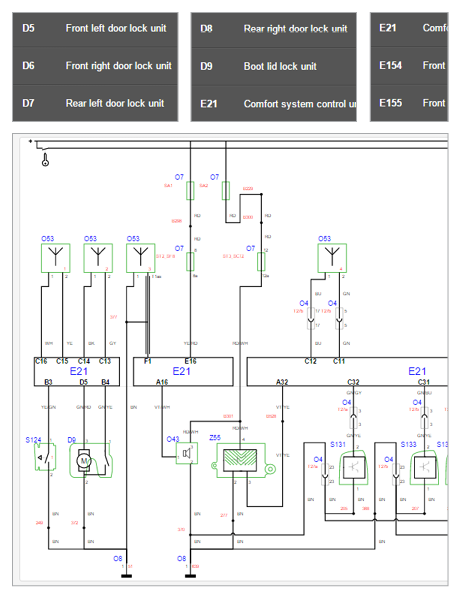

Comfort wiring diagrams

Clear, 'localised' wiring schematics.

Clear, ‘localised’ wiring schematics for all key vehicle features, with wire and component trace functionality for fast, efficient, first-time fixes.

| Subject | Features |

|---|---|

Comfort wiring diagrams Comfort wiring diagrams |

|